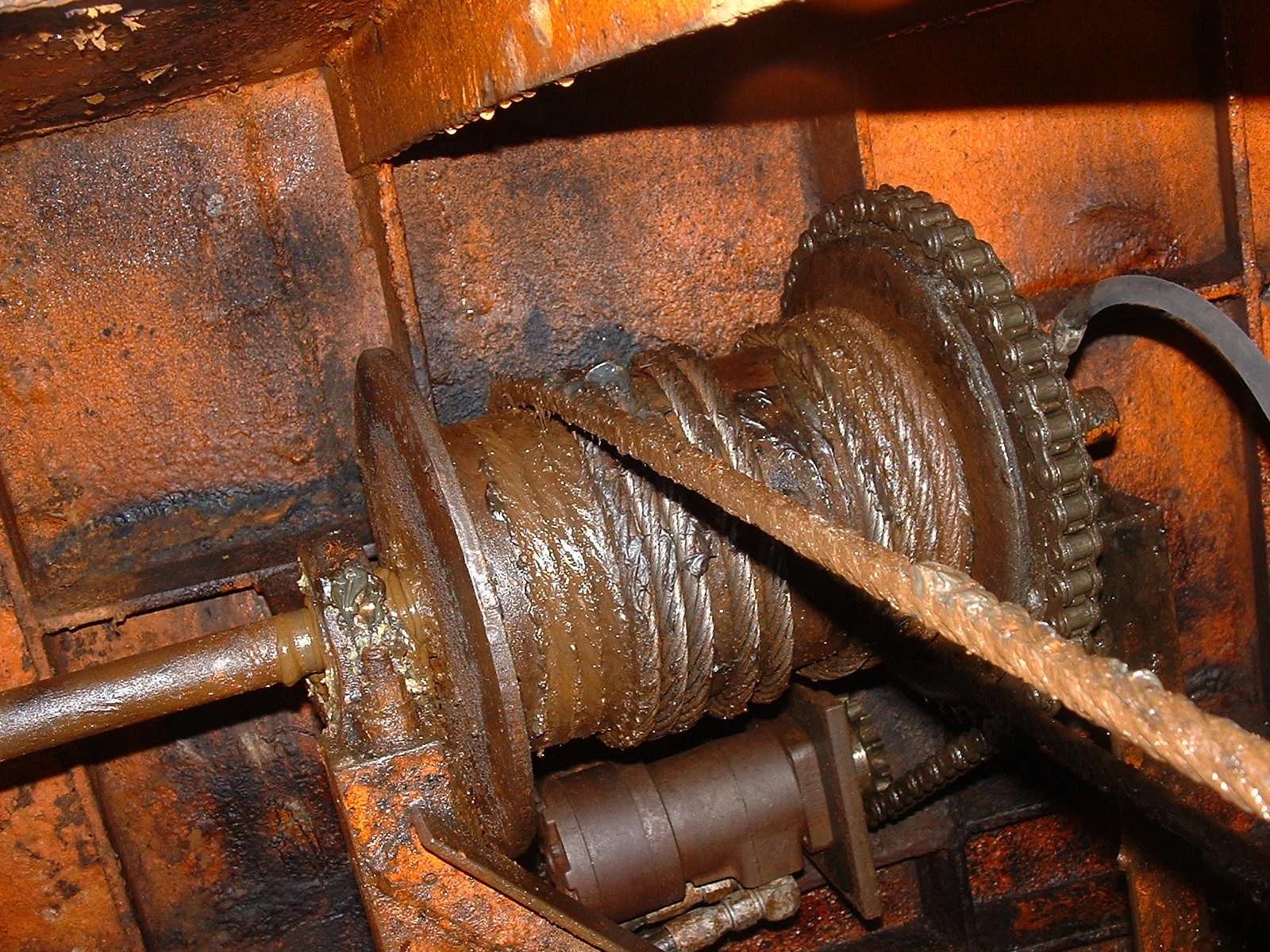

Built on Lake Roosevelt by Howard Dolph for Lafferty Transportation. Launched in 1951 as the Grant Dixon I. She worked for many years at Kettle Falls behind the Grand Coulee Dam. In those days she reportedly had a P & H 171 Horsepower diesel engine. Around 1968 she was sold to Knappton & Brusco working mainly on the Columbia River. The history shows she may have had a Murphy V-8 Main engine at that time, but no proof has been found to corroborate this. We do know that around 1990 or so she was purchased by Kenneth Baney and re named the Dixie after a family member. Not sure when the Cummins was installed but in 2003 it was purchased in Ketchikan AK by Fremont Tugboat Company and barged to Seattle. After a major refit that lasted over a year, she finally went back in the water in 2004 to finish the house and interior restoration. On _____2004?2005 Dixie did her first tow in her new Fremont colors, moving the Foss 300 in Lake Union. In April of 2011 we moved the tow winch and all the deck gear behind the house, cut out and re plated the deck covering the fuel tank up to the back of the house. Replaced the tow winch on a raised pedestal, moved the face wire winch and re installed the crane on top of that to allow for more deck room. In 2013 we tore down the main engine and did a top end rebuild sending the heads out for re surfacing and all injectors for rebuild and testing. Later in the summer of 2016 we cut off all the bulwarks from the bow to the back of the house, cut out and re plated the first 3 feet of the forward deck, cut off most of the deck over the engine room and re plated, cut off all the railings and installed new. Built new bullnose, bulwark (raising the bow 4 inches) . Then built and installed a new aluminum mast, upper station with railings. All new navigation lights, vhf radios, antennas, plotters, wind meter, and dash to accommodate all the bells and whistles needed for operations. The following year in 2017 we removed all the old steel deck plates in the engine room, installed new aluminum diamond plate and welded in framing for the generator, tool chest, additional battery storage, air compressor and the oil change pump system. Drydocking in late 2017 we painted the hull and bottom, welded on 2 new pad eyes for the bow fendering and added 2 rollers on the back deck and finally removed the face wire blocks to save room on deck and prevent tripping hazards. The Dixie has been in service for almost 15 years with only a few short weeks out of service for dry docking or engine maintenance in that time. Not only a great workboat but also quite comfortable to be on for days on end. Also using her to view the fireworks and as our family swim platform in the summer months. The Tug Dixie is the work horse of the fleet and still looks pretty good for a tugboat that has been in service for over 65 years and counting.